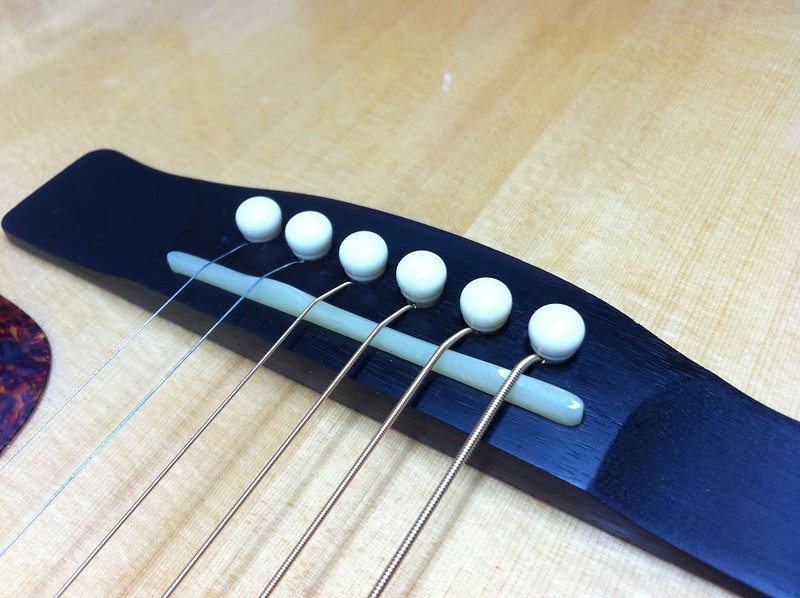

This acoustic has recently made it into regular rotation during its owner’s gigs. While it’s a fine guitar with some very nice burl ash back and sides, he wanted to improve the overall tone and sustain. So we replaced the plastic nut, saddle and bridge pins with custom made bone. The reason I use bone is because it a much denser material than plastic and transfers vibration much more efficiently. The more vibration that is transferred from the strings to the soundboard, the more rich tone and sustain the guitar will have.

I started with a bone blank, took measurements with a micrometer, then had at it with a belt sander, various files, sandpaper and ended with a polishing wheel.

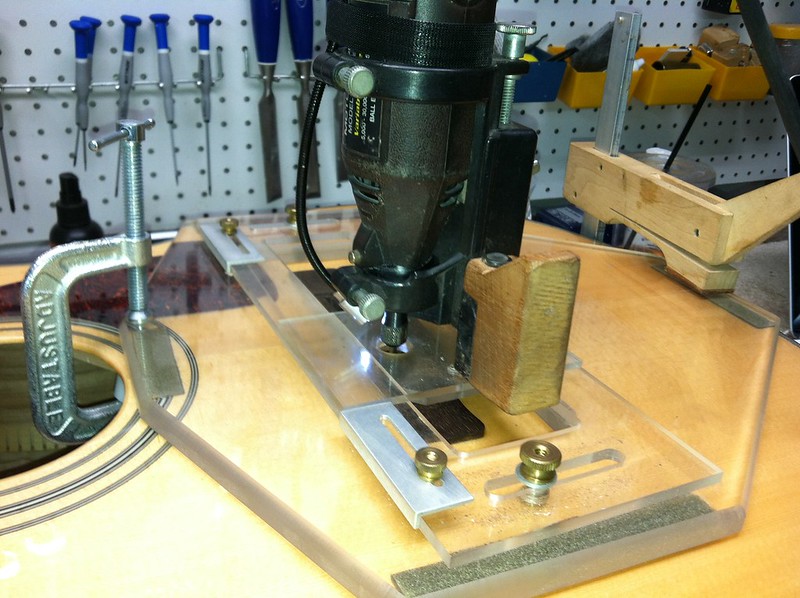

For the saddle, the existing saddle slot in the bridge had a less than level bottom and the walls were a bit uneven. So I decided to widen the slot by about 1/64 of an inch to correct these imperfections. I then cut and shaped the saddle to perfectly fit the new slot dimensions.

Next up were seating the new bridge pins. They had a bit larger radius than the factory plastic pins. Nothing that a quick 2 or 3 turns with a reamer couldn’t fix.

For the nut, once it was cut, shaped polished and glued into place I needed to add the string slots. To determine the exact placement of the slots requires some precise measurements and some basic math. Sounds easy, but being dyslexic, I like to triple-check the numbers before making the first cuts with the files.